[Qingdao, China, October 14, 2024] Today, the CO-NELE laboratory welcomed a customer with a unique challenge. The customer requested to utilize our advanced mixed granulation technology to conduct a granulation experiment on a mixture of aluminum oxide, iron oxide, and bentonite, with strict requirements for the final particle size to be controlled between 0.5 and 2 mm. Faced with this complex material's process requirements, the CO-NELE technical team precisely responded, completing the experiment using our independently developed CEL1 series

laboratory granulator. The excellent results earned high praise from the customer.

The customer's material formulation featured the high hardness of aluminum oxide, the high specific gravity of iron oxide, and the viscous bentonite. These three elements placed extremely high demands on the equipment's shear, mixing, and agglomeration capabilities during the granulation process. The narrow particle size distribution range (0.5-2 mm) placed a rigorous test on the equipment's control accuracy and stability.

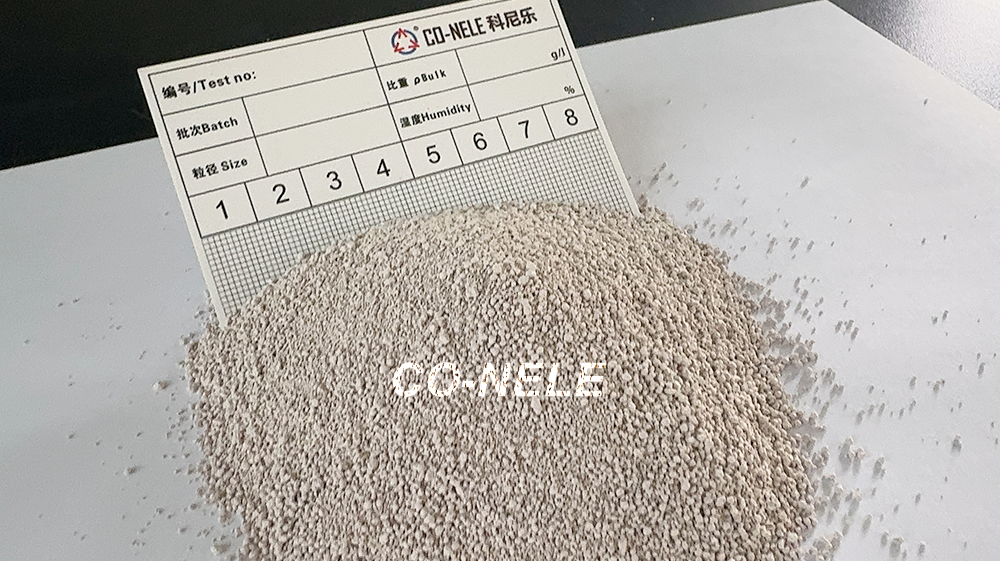

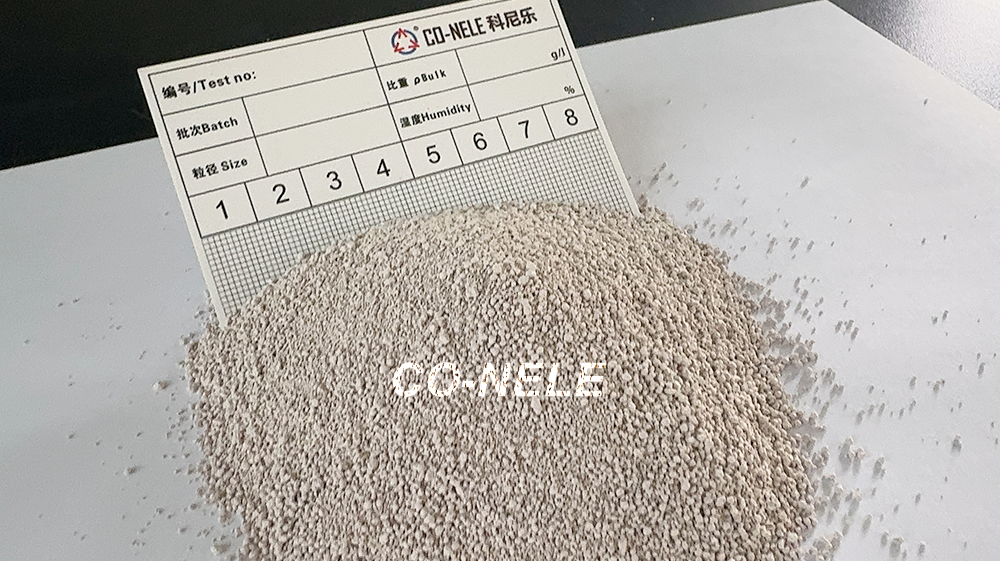

The experiment went smoothly. The CEL1 series granulator demonstrated strong adaptability. By precisely controlling parameters such as the impeller and cutter speeds and mixing time, it successfully blended diverse raw materials into dense granules.

The experimental results showed:

Excellent particle size uniformity: The majority of the produced granules fell within the target range of 0.5-2 mm, exhibiting a concentrated distribution with no noticeable oversized or overfine particles.

The yield rate far exceeded expectations: Thanks to the equipment's efficient operation and stable performance, the yield rate in this experiment reached an exceptionally high level, effectively reducing material waste.

After carefully inspecting the finished granules, the customer expressed "extreme satisfaction" with the results. He specifically stated, "The CEL1 granulator from Co-Nele not only solved our multi-component granulation challenges, but its excellent particle size control and high yield provide reliable data support and a process model for our subsequent industrial production."

Possible applications for these composite particles include:

Catalysts: Used in high-temperature chemical reactions, such as as a carrier for desulfurization and denitrification catalysts, with the iron oxide providing the active component.

Adsorbents: Used to treat heavy metals or organic matter in wastewater.

Magnetic materials: If the iron oxide is Fe₃O₄ (magnetite), magnetic spherical particles can be prepared, facilitating separation and recovery from reaction systems.

Ceramic pigments or raw materials.

Committed to "creating value for customers through technological innovation," Co-Nele is committed to providing global customers with a complete suite of intelligent mixing and granulation solutions, from laboratory to industrial production. We look forward to collaborating with partners from more industries to overcome process challenges and drive industry progress.

About Co-Nele:

Co-Nele is a high-tech enterprise specializing in the research, development, manufacturing, and service of mixing and granulation equipment. Our product line includes a wide range of mixers, granulators, and production lines, widely used in a variety of fields, including chemicals, pharmaceuticals, magnetic materials, ceramics, solid waste, and metallurgy. Our products are renowned both domestically and internationally for their stable performance and superior quality.