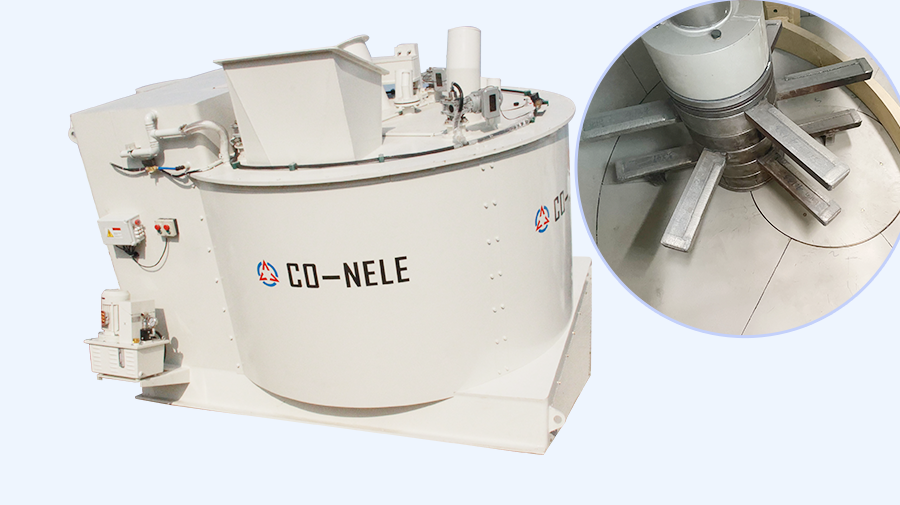

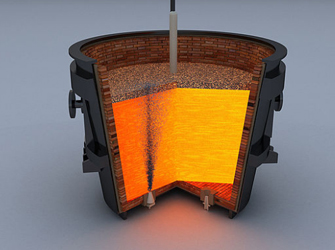

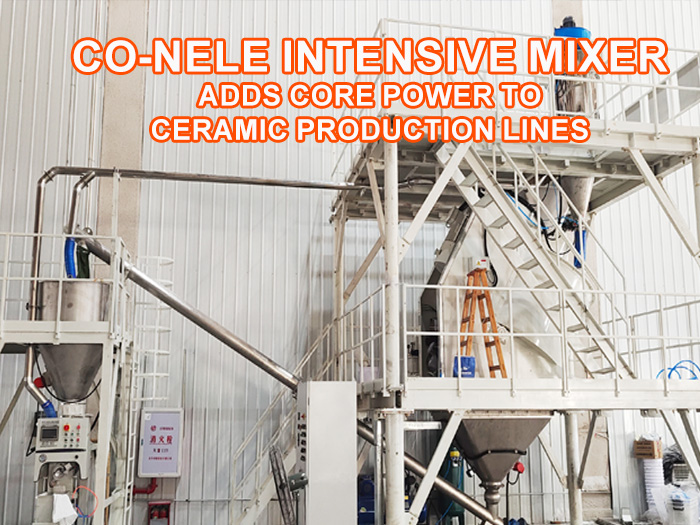

CoNele's intensive mixers are widely used globally in industries such as chemicals, metallurgy, ceramics, building materials, and new energy, renowned for their efficient, uniform, and reliable mixing performance. Their core technology utilizes countercurrent mixing to achieve extremely high mixing uniformity in a short period of time.

Intensive mixers unique mixing principle can ensure that 100% of the materials are mixed, and the best product quality can be obtained in the shortest mixing time for batch operation.

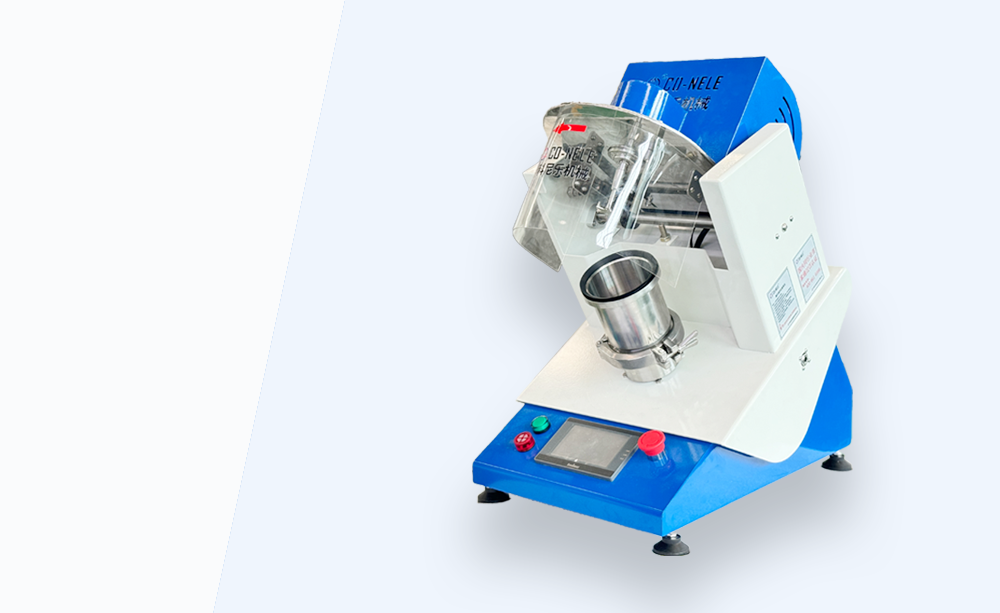

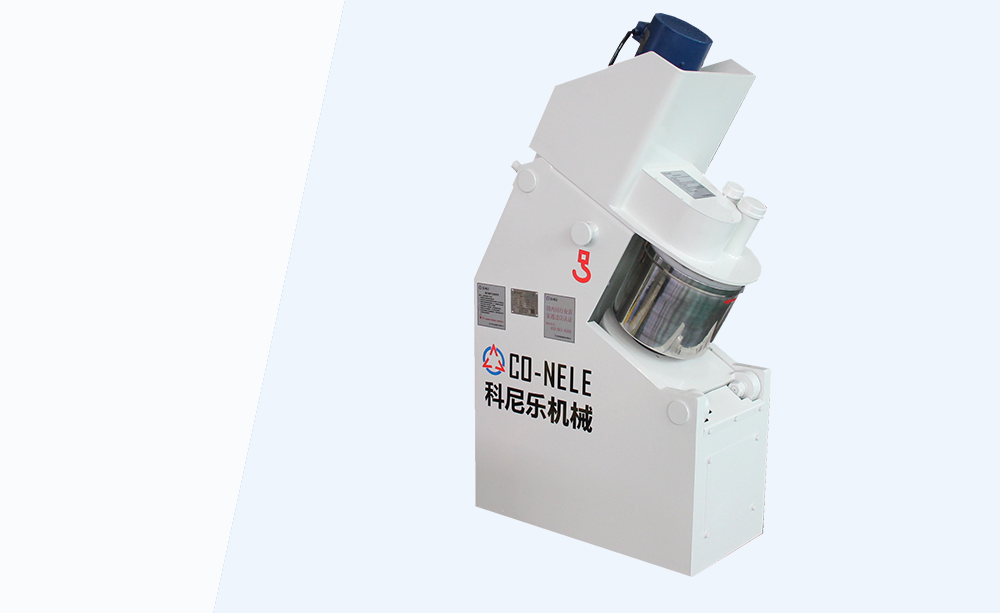

While the mixing device is rotating at high speed, the cylinder is driven by the reducer to rotate, and the mixing cylinder is inclined at a certain angle to realize a three-dimensional mixing mode, which makes the material turn more violently and mix more evenly.

Intensive mixers mixing direction is divided into forward and reverse.

Intensive mixer can multiple processes such as mixing, granulating/pelletizing, kneading, and slurrying can be handled in a single machine by adjusting operating conditions.

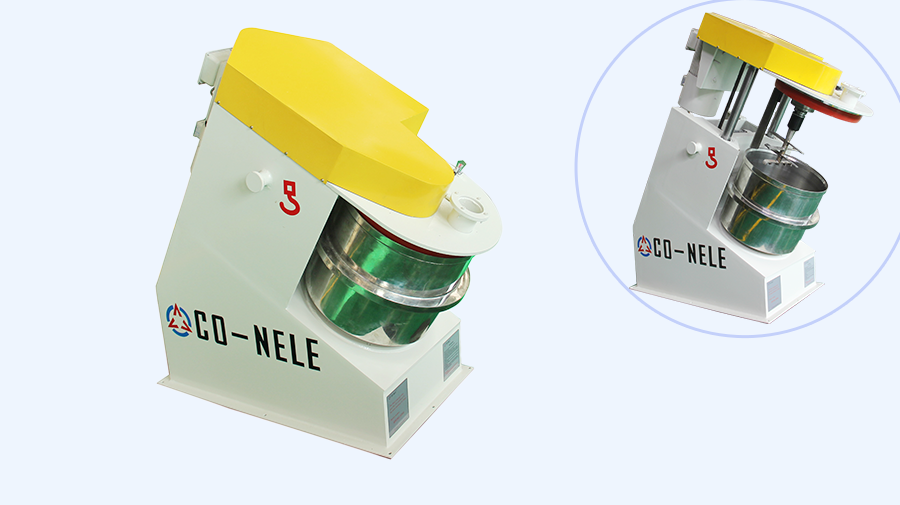

A wide range of lineup is available, from 500ml/batch up to 7,000L/batch for Type-CR (mixing pan inclined type) and up to 12,000L for Type-CD (mixing pan horizontal type), Continuous intensive mixer achieves an output of 80t/h-600t /h.The most suitable machine type will be selected according to your requirements.

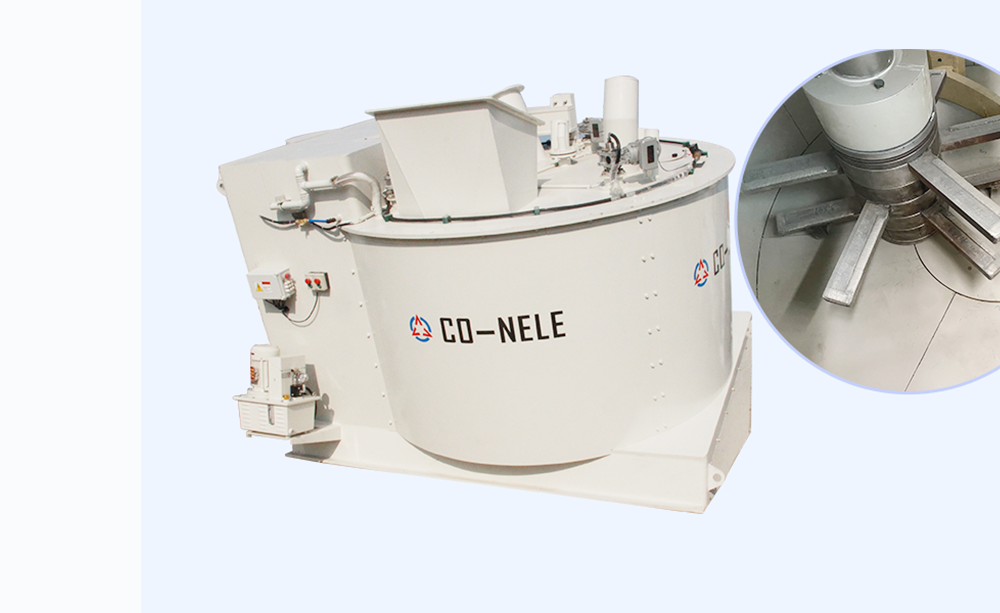

Three core components of CO-NELE Intensive Mixer are: an eccentrically positioned rotor tool (mixing tool), tool set (bottom/wall scraper), and the rotating mixing pan (mixing vessel).

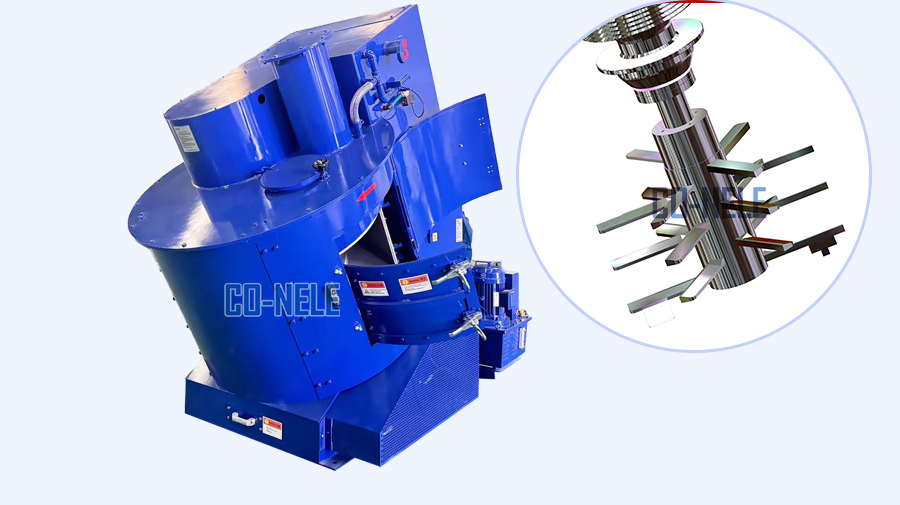

1. Rotor tool (mixing tool)

1. Rotor tool (mixing tool)

Rotor tool is positioned eccentrically to the center of the mixing pan, enabling efficient shear force onto the material. The speed can be set according to the purpose of processing, from high speed for high shear force to low speed for gentle agitation. The design and direction of rotation can also be selected according to the process requirements. A bottom tool attached to the bottom end of the rotor tool prevents build-up of material on the bottom of the mixing pan.

2. Tool set (bottom/wall scraper)

Tool set prevents build-up of material on the wall and bottom of the mixing pan. It also changes the direction of material flow and promotes the homogenization of the process material inside the mixer.

3. Mixing pan (mixing vessel)

The rotating mixing pan moves the mix into the path of the mixing tool.

Type of Intensive Mixer

| Type | Mixing Capacity | Model of Operation | ||

| liters | Kg max. | Batch | Continuous | |

| CEL1s | 0.1-0.5 | 0.8 | Batch | |

| CLE01 | 0.3-1 | 1.6 | batch | |

| CEL05 | 1-5 | 8 | batch | |

| CEL10 | 3-10 | 16 | batch | |

| CR02 | 1-5 | 8 | batch | |

| CR04 | 3-10 | 16 | batch | |

| CR05 | 8-25 | 40 | batch | |

| CR08 | 16-50 | 80 | batch | |

| CR09 | 33-100 | 120 | batch | |

| CRV09 | 50-150 | 240 | batch | |

| CR11 | 80-250 | 360 | batch | |

| CR15M | 110-350 | 600 | batch | continuous |

| CR15 | 160-500 | 840 | batch | continuous |

| CRV15 | 200-600 | 1200 | batch | continuous |

| CR19 | 150-750 | 1440 | batch | continuous |

| CRV19 | 330-1000 | 1800 | batch | continuous |

| CR20 | 400-1250 | 2400 | batch | continuous |

| CR24 | 500-1500 | 3000 | batch | continuous |

| CRV24 | 650-2000 | 3600 | batch | continuous |

| CR29 | 1000-3000 | 4800 | batch | continuous |

| CD29 | 1200-3500 | 7200 | batch | continuous |