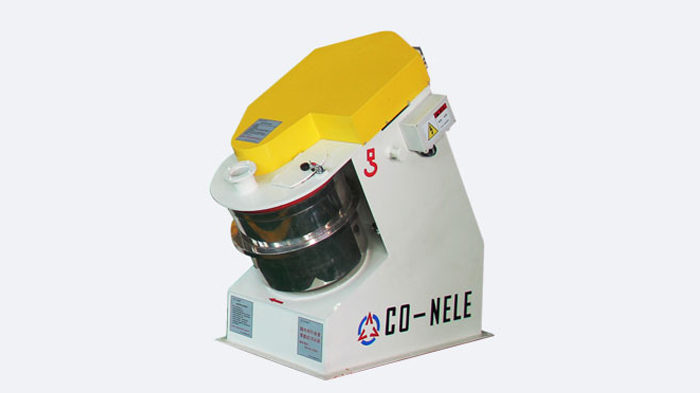

Intensive Mixer

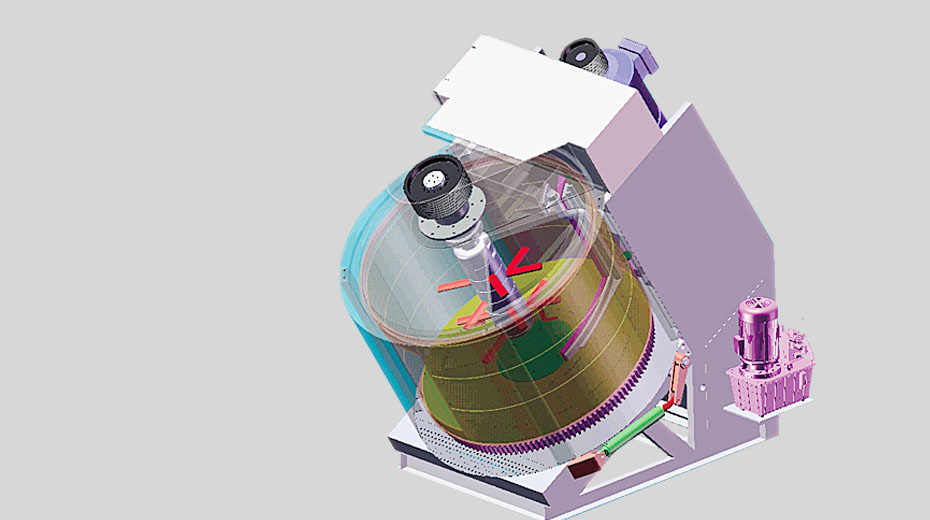

The Intensive Mixer principles have countercurrent or cross-flow .

For batch production or continuous production.

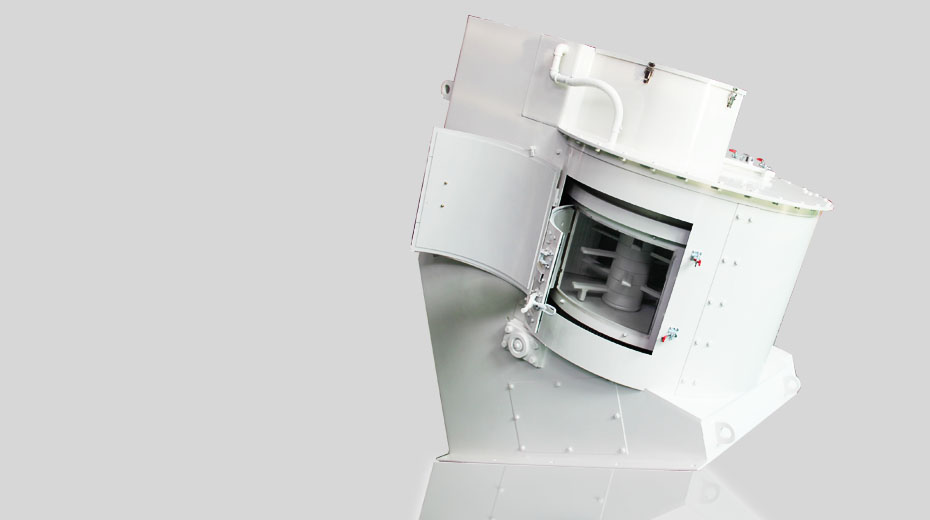

Optimum mixing quality and uniformity can be achieved in a short time.

Mixing and granulation can be achieved in the same machine.......

CO-NELE Test Center provides a one-stop test site and a platform for international experience exchange.Laboratory mixer CEL5/CEL10/CR02/CR04 can meet the requirements of different industries for different materials preparation.

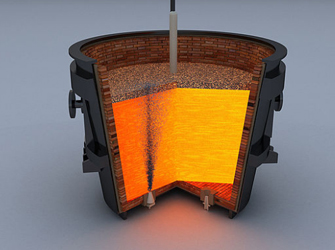

Our intensive mixer is a synonym for optimum mixing technology

Function :mixing, granulating, reflecting, emulsifying, dispersing, separating, plasticizing, forming, venting, breaking, fibrillating, disintegrating, coalescing

The mixing pan can be arranged either horizontally or at an optimized angle of inclination to suit the particular requirements.

Type Of Intensive Mixer

| Type | Out capacity(L) | Out weight(Kg) |

Main planet(nr) |

|---|---|---|---|

| CEL5/CR02 | 5 | 6 | 1 |

| CEL10/CR04 | 10 | 12 | 1 |

| CR05 | 25 | 30 | 1 |

| CRO8 | 50 | 60 | 1 |

| CR09 | 100 | 120 | 1 |

| CRV09 | 150 | 180 | 1 |

| CR11 | 250 | 300 | 1 |

| CR15 | 350 | 420 | 1 |

| CRV15 | 500 | 600 | 1 |

| CRV15H | 600 | 720 | 1 |

| CR19 | 750 | 900 | 1 |

| CRV19 | 1000 | 1200 | 1 |

| CR20 | 1250 | 1500 | 1 |

| CR24 | 2000 | 2400 | 1 |