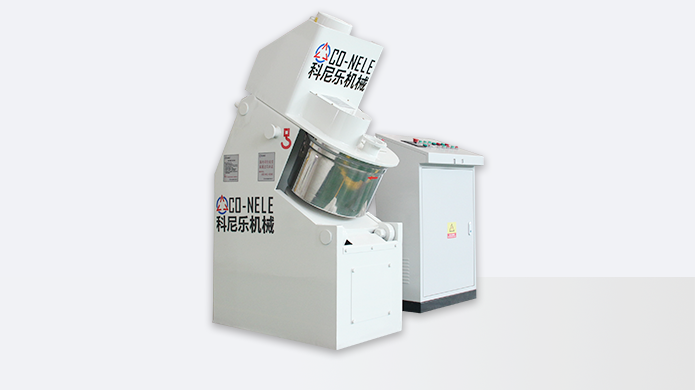

Laboratory Intensive Mixer

Mixers for research, development and small production

The laboratory intensive mixers of the CR series are available in sizes of 5 to 50 liters. They have all the features of the multifunction CO-NELE mixing system and can be used for a great variety of challenging processing applications, such as mixing, granulating, and many more.

Our intensive mixer is a synonym for optimum mixing technology

The outstanding feature of the CO-NELE intensive mixer is that it separates the transportation of the mix from the actual mixing process.

The mixing pan can be arranged either horizontally or at an optimized angle of inclination to suit the particular requirements.

Type Of Intensive Mixer

| Type | Out capacity(L) | Out weight(Kg) |

Main planet(nr) |

|---|---|---|---|

| CEL5/CR02 | 5 | 6 | 1 |

| CEL10/CR04 | 10 | 12 | 1 |

| CR05 | 25 | 30 | 1 |

| CRO8 | 50 | 60 | 1 |

| CR09 | 100 | 120 | 1 |

| CRV09 | 150 | 180 | 1 |

| CR11 | 250 | 300 | 1 |

| CR15 | 350 | 420 | 1 |

| CRV15 | 500 | 600 | 1 |

| CRV15H | 600 | 720 | 1 |

| CR19 | 750 | 900 | 1 |

| CRV19 | 1000 | 1200 | 1 |

| CR20 | 1250 | 1500 | 1 |

| CR24 | 2000 | 2400 | 1 |