This highly efficient integrated mixing and granulation solution for the ceramics industry automates the entire process, from automatic loading to discharging and packaging. The project was successfully delivered and received high customer recognition.

A fully automated production line for ceramic raw materials, equipped with a Conele CR11 500-liter intensive mixer, has been successfully installed and commissioned and officially delivered to the client for production. With its efficient mixing and granulation performance and fully automated control system, this line has significantly improved the client's production efficiency and product consistency, becoming a model example of intelligent upgrading in the ceramics industry.

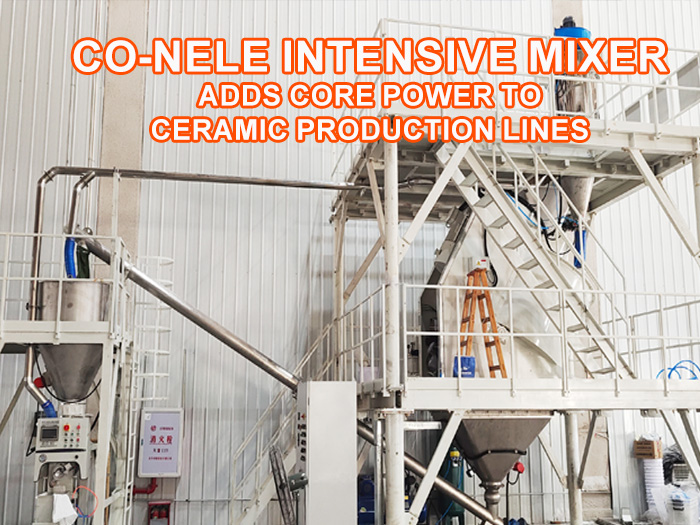

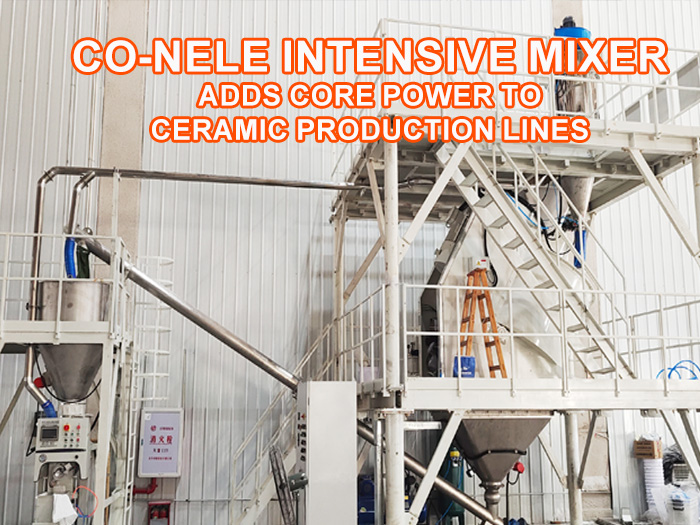

Driven by the wave of industrial automation, the ceramics industry is undergoing a profound transformation in its production model. This week, a highly anticipated ceramic raw materials preparation project was successfully completed: the fully automated production line, featuring a Conele CR11 500-liter intensive mixer as its core equipment, passed final acceptance and was officially delivered to the client. This project achieves unmanned operation throughout the entire process, from automatic raw material loading, precise mixing and granulation, to automatic discharging and packaging, marking a key step for the ceramics company on the path to intelligent manufacturing.

The ceramics company is committed to producing high-quality ceramic products. Faced with increasingly fierce market competition, the client encountered bottlenecks in its existing raw material preparation process: traditional mixing equipment lacked uniformity, resulting in suboptimal granulation and heavy reliance on manual operation, leading to low production efficiency, poor batch stability, and high labor costs. The client urgently needed an efficient solution that could consistently produce high-quality ceramic raw materials and seamlessly integrate into a fully automated production line.

Solution: A one-stop automated production line centered around the Co-Nel CR11 Intensive Mixer.After in-depth technical discussions and solution verification, Co-Nel customized a complete solution centered around the CR11 500-liter intensive mixer.

Core Equipment: The CR11 Intensive Mixer: Known for its powerful shear and convection mixing principles, this mixer is particularly well-suited for ceramic raw material processes requiring highly uniform mixing and simultaneous granulation. Its 500-liter capacity perfectly matches the production line's capacity requirements, ensuring excellent mixing uniformity and ideal particle size distribution for every batch.

Fully Automatic Control System: The entire production line is fully automated using a central control room. The system precisely controls every parameter, including feed rate, mixing time, impeller speed, and granulation liquid dosage, completely eliminating human error and ensuring high batch-to-batch consistency.

Seamless Automation: The system integrates an automatic feeder (such as a bucket elevator or pneumatic conveying system) with an automatic discharge and packaging unit. After mixing and granulation, the material is automatically discharged through a bottom outlet and directly conveyed to a quantitative packaging machine for packaging, creating an efficient, closed-loop production process.

Project Results: Smooth Delivery, Immediate Benefits

Project Results: Smooth Delivery, Immediate BenefitsThe project has now been fully installed and commissioned, and has been handed over to the customer's production team. Operational results demonstrate:

Significantly Improved Production Efficiency: The fully automated process has shortened batch production cycles by approximately 30%, achieving continuous, highly efficient production.

Improved Product Quality: The CR11 mixer delivers superior mixing and granulation results, significantly increasing ceramic yields.

Effectively Reduced Operating Costs: Automated production reduces reliance on skilled operators, lowers labor costs, and minimizes material waste.

Improved working environment: Enclosed, automated production reduces dust fugitives, creating a cleaner and safer working environment.

The customer project manager expressed satisfaction: "We are very pleased with the performance of the Co-nele CR11 mixer and its automated production line. From project planning to installation and commissioning, the Co-nele team demonstrated a high level of professionalism. This production line not only addresses our existing pain points but also lays a solid foundation for future expansion and intelligent development."

About Co-neleCo-nele is a technology-driven company specializing in the research, development, manufacturing, and sales of high-end mixing equipment. Its product line includes a wide range of high-performance mixers and kneaders, widely used in ceramics, refractory materials, chemicals, environmental protection, and lithium battery cathode and anode materials. The company consistently creates value for customers through technological innovation and is committed to providing efficient and reliable mixing solutions to industrial users worldwide.