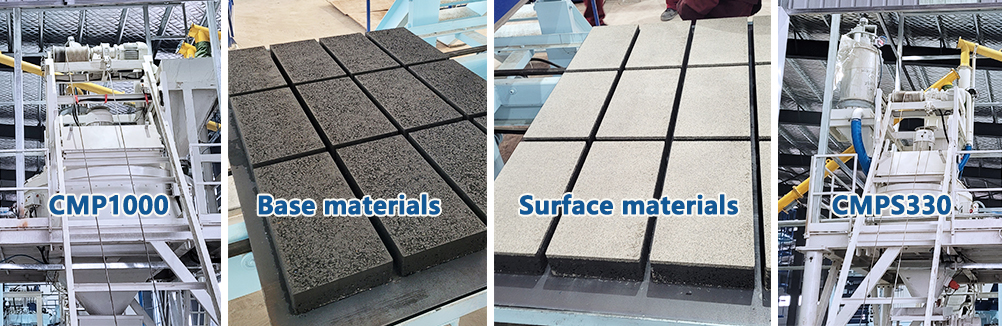

In a key infrastructure construction area in Brazil, a company specializing in the production of high-grade paving bricks, permeable bricks, and imitation stone paving bricks has long faced the challenge of balancing high-intensity continuous production with stringent product consistency requirements. To ensure that the paving bricks meet high standards in terms of strength, appearance, and color stability, the company selected CO-NELE planetary concrete mixing solutions for its busy paving brick production line.To date, the production line has been operating continuously and stably for over 3 years, with the two core mixing units consistently maintaining efficient and reliable operation, becoming a crucial guarantee for the customer's production capacity and quality.Project Configuration: Base Material + Surface Material Step-by-Step Mixing ProcessThis paving brick production line adopts an advanced "base material + surface material" step-by-step mixing process, effectively balancing the structural strength of the bricks with the surface decorative effect. The core configuration of the entire line consists of two CO-NELE planetary mixers, each undertaking the mixing tasks of different material systems.Core Equipment 1: CMP1000 Vertical Shaft Planetary Concrete Mixer (Base Material)Discharge Capacity: 1000 LMixing Power: 37 kWEquipment Weight: Approximately 6200 kgApplication Features:The CMP1000 adopts a vertical shaft planetary mixing structure, with multiple sets of planetary mixing arms and scrapers forming a full-coverage mixing trajectory, achieving a dead-angle-free, high-shear, and high-density mixing effect.This model is particularly suitable for dry-hard concrete and low water-cement ratio formulations. In the mixing of base materials for paving bricks, it can significantly improve concrete uniformity and molding strength, providing a stable foundation for subsequent pressing and curing.Core Equipment 2: CMPS330 Planetary Concrete Mixer (Surface Material)Discharge Capacity: 330 LMixing Power: 15 kWApplication Advantages:The CMPS330 is designed specifically for high uniformity and high color consistency surface concrete, capable of achieving thorough dispersion of pigments, cement, and fine aggregates in a short time.In the production of colored paving bricks and imitation stone bricks, this equipment effectively avoids color differences, spots, and stratification problems, significantly improving the decorative effect and market competitiveness of the paving bricks.

Application Results and Customer Value

✔ Stable and reliable equipment operation under high load for many consecutive years✔ Simultaneous improvement in base layer strength and surface aesthetics✔ Consistent finished brick size, uniform color, and stable quality✔ Meeting the large-scale delivery demands for high-end paving bricks in the Brazilian marketThe successful operation of this project fully demonstrates the maturity and adaptability of CO-NELE's planetary mixing technology in the paving brick, paving stone, and concrete product industries.CO-NELE: A core equipment supplier empowering global paving brick productionCO-NELE has always focused on the research and application of planetary concrete mixing technology, providing global customers with professional support ranging from equipment selection to complete line solutions. We appreciate the long-term trust of our Brazilian customers and will continue to empower more concrete product enterprises to achieve stable production and quality upgrades with high-performance and highly reliable equipment.