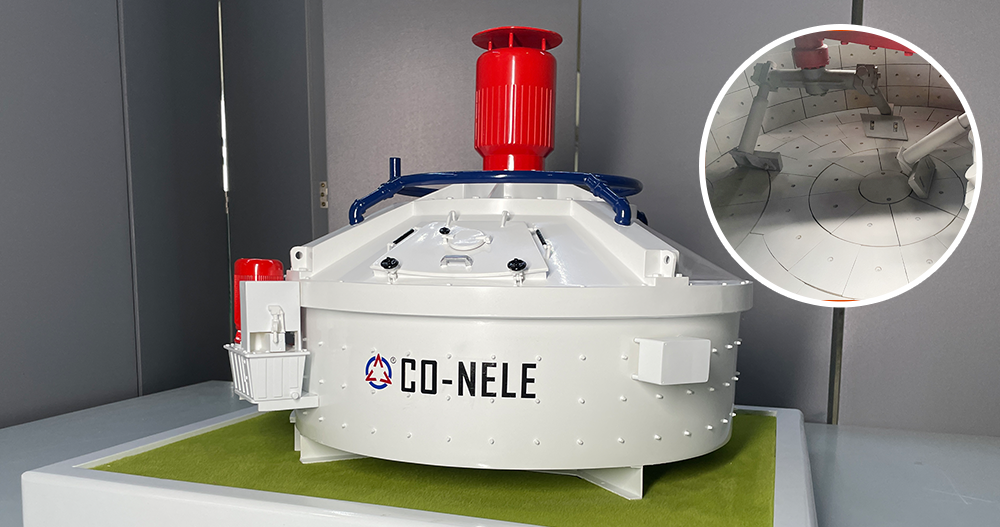

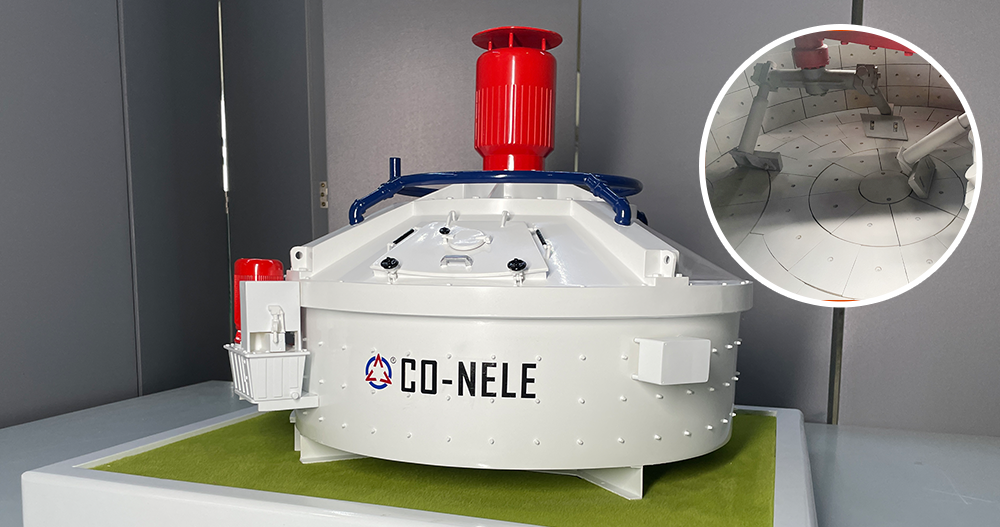

CONELE An innovative mobile UHPC batching plant solution has been successfully applied to a C120-grade ultra-high-performance concrete (UHPC) road paving project. The core of this project is to optimize the UHPC on-site construction process. By moving the batching plant directly to the construction site, the application cost and logistical complexity of the ultra-high-strength concrete have been significantly reduced.UHPC Concrete Mixers in Modular UHPC Mobile Mixing Plants for C120-Grade UHPC Road PavingHow a "walking UHPC batching plant" solves the challenges of on-site UHPC applicationAlthough UHPC is renowned for its ultra-high compressive strength exceeding 150 MPa and exceptional durability, its traditional production and transportation methods have limited its large-scale application in conventional projects. Long-distance transportation of ready-mixed UHPC is not only costly but also poses significant challenges to maintaining concrete workability. This project aims to achieve local production and immediate construction of C120-grade UHPC through a flexible and efficient solution. Solution: A Modular, Mobile "On-Site Mixing Plant"CONELE UHPC mobile batching plant used in this project proved to be a key breakthrough. The core advantage of this solution lies in its highly integrated modular design and exceptional relocation flexibility.CO-NELE Mixing plant features a unique two-tiered design:The top tier houses the "heart" of the plant—a large-capacity 1000-ton planetary concrete mixer. This mixer is renowned for its powerful mixing power and uniformity. Its complex combination of orbital and rotational motion ensures perfect dispersion of steel fibers within the dense UHPC slurry, preventing clumping and contributing to the C120's design strength.

Solution: A Modular, Mobile "On-Site Mixing Plant"CONELE UHPC mobile batching plant used in this project proved to be a key breakthrough. The core advantage of this solution lies in its highly integrated modular design and exceptional relocation flexibility.CO-NELE Mixing plant features a unique two-tiered design:The top tier houses the "heart" of the plant—a large-capacity 1000-ton planetary concrete mixer. This mixer is renowned for its powerful mixing power and uniformity. Its complex combination of orbital and rotational motion ensures perfect dispersion of steel fibers within the dense UHPC slurry, preventing clumping and contributing to the C120's design strength.The bottom tier serves as the support structure and control center. At the unloading area, a specially designed chute seamlessly connects to transport vehicles. This chute allows for smooth and efficient unloading of the finished, high-flowing C120 concrete into the dedicated UHPC transport tankers waiting below.

UHPC Planetary Concrete Mixer Technical Parameters

Discharge Capacity: 1000L (1.0 m³)Feed Capacity: 1500LMixer Motor Power: 37kW - 45kWMachine Weight: Approximately 6200kgDischarge Method: Hydraulic DischargeUHPC Mixing Cycle: ≤ 5minPlanetary Concrete Mixer for UHPCOperating Principle: It utilizes a vertical-shaft planetary countercurrent bidirectional mixing method. The mixing arm revolves around the main axis while also rotating, creating a complex motion path within the mixing drum, achieving robust mixing without dead angles.Performance: This design enables it to mix a wide range of concrete mixes, from dry hard to plastic, and is particularly effective for materials such as UHPC (ultra-high performance concrete), which require extremely high uniformity. The equipment typically features low noise and high torque, and the discharge door has a well-sealed design, helping to control dust.On site, a complete, efficient closed-loop workflow was established: After raw materials were efficiently mixed in the mobile batching plant's 1,000 planetary concrete mixers, the resulting fresh UHPC was directly unloaded via chutes into transport tankers. Transporting them over extremely short distances, it reached the paving surface dozens of meters away. This system truly achieves "one-stop mobility as the construction site changes." Its modular design allows the entire batching plant to be quickly disassembled, moved, and reassembled at the new site, fundamentally reducing the significant transportation costs associated with fixed-site production and providing the general contractor with unprecedented flexibility and cost-effectiveness.

This system truly achieves "one-stop mobility as the construction site changes." Its modular design allows the entire batching plant to be quickly disassembled, moved, and reassembled at the new site, fundamentally reducing the significant transportation costs associated with fixed-site production and providing the general contractor with unprecedented flexibility and cost-effectiveness. This case successfully demonstrated the feasibility and significant advantages of using mobile UHPC batching plants in large-scale linear projects, such as roads and bridges. It is not only a successful demonstration of UHPC concrete mixer technology, but also marks that the application of ultra-high performance concrete has broken away from the constraints of fixed mixing stations and taken a solid step towards a new model of distributed and on-site "mobile manufacturing", providing a replicable example for the intelligent and efficient upgrade of future infrastructure.

This case successfully demonstrated the feasibility and significant advantages of using mobile UHPC batching plants in large-scale linear projects, such as roads and bridges. It is not only a successful demonstration of UHPC concrete mixer technology, but also marks that the application of ultra-high performance concrete has broken away from the constraints of fixed mixing stations and taken a solid step towards a new model of distributed and on-site "mobile manufacturing", providing a replicable example for the intelligent and efficient upgrade of future infrastructure.