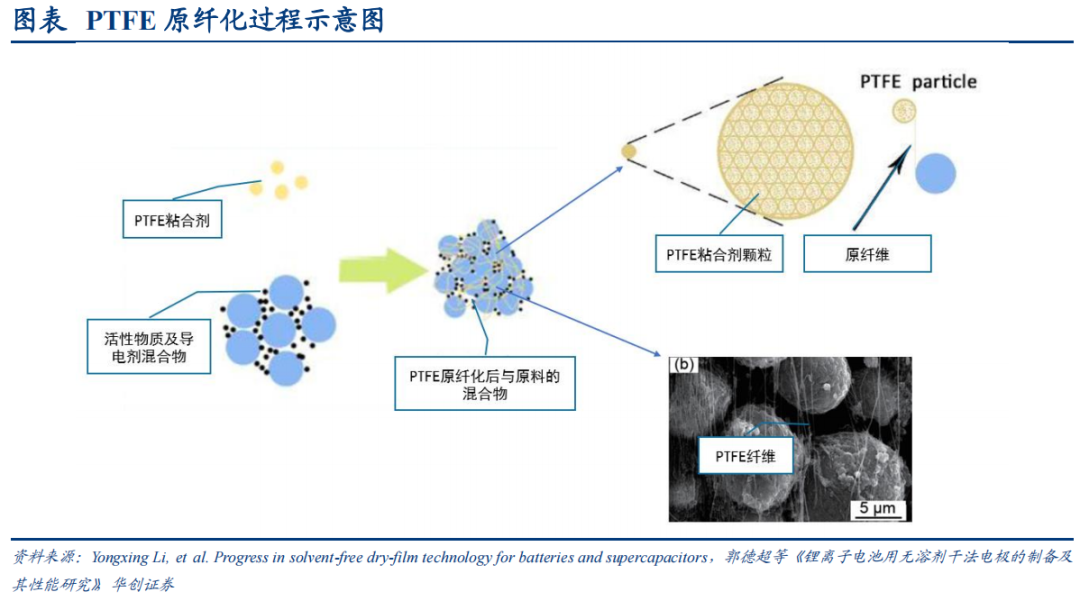

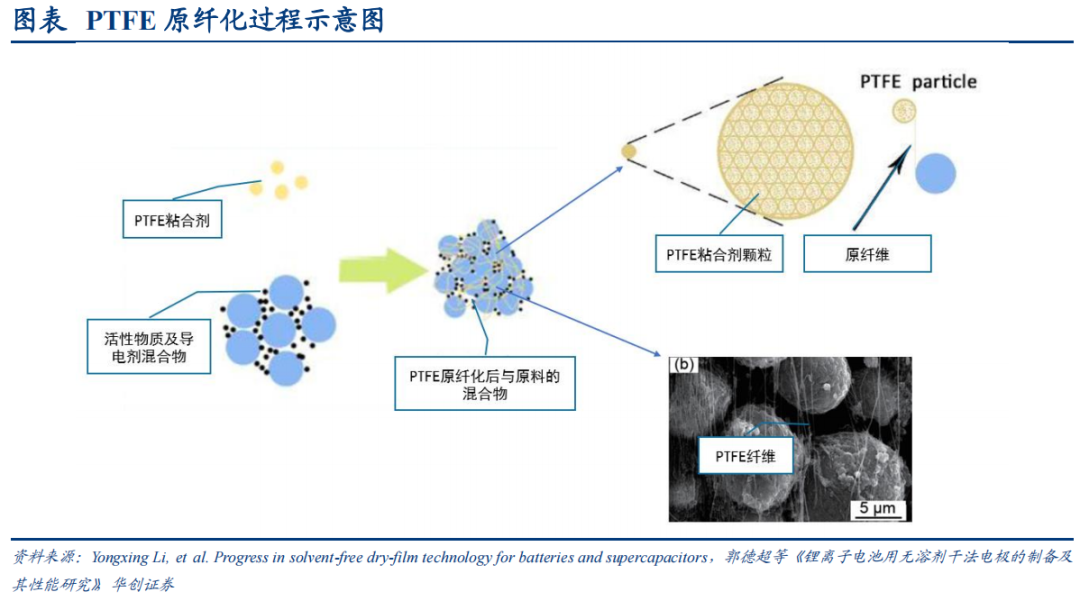

Dry stirring fiberization+dry film formation all-solid-state technology is a key process innovation in the current solid-state battery manufacturing field.Its core lies in improving electrode production efficiency,reducing costs,and optimizing battery performance through a solvent-free process.1.Process flowDry technology mainly includes three core links:mixing(dry stirring),fiberization,and film formation:Mixing(CO-NELE Intensive Mixer):Mix active materials(such as positive/negative electrode materials),solid electrolytes,conductive agents,and binders(such as PTFE)in an anhydrous environment to form a uniform powder.Fiberization:Through high-speed shearing,extrusion or honey refining processes,the binder(such as PTFE)forms a mesh fiber structure to enhance the mechanical strength and conductivity of the material.For example,CO-NELE dry electrode mixer equipment.Film formation:Press the mixed material into a self-supporting film and then compound it onto the current collector.Ensure the uniformity and high density of the membrane.2.Key equipmentDry electrode fiberizing mixer equipment(CO-NELE Intensive Mixer):Improve efficiency and reduce powder loss.Intensive mixer is used for uniform mixing and efficient fiberization.

Technical advantages

1.Cost and efficiencyThe use of solvents and drying steps are eliminated,energy consumption is reduced by more than 30%,and equipment investment is reduced by about 20%.CO-NELE battery mixer equipment increases the efficiency of pole piece manufacturing by 50%and reduces production costs by 25%.2.Performance improvementHigh compaction density:Fiberized binder reduces the obstruction to ion conductionHigh energy density:Dry film formation can reduce interface impedance and increase battery energy density by 10%-20%.Process stability:Mixing uniformity,fiberization degree and film strength are greatly affected by the physical properties of raw materials,and parameters(such as temperature and shear rate)need to be optimized.Dry mixing fiberization+dry film formation technology has become the core path for mass production of all-solid-state batteries through solvent-free,high-precision equipment integration and material process innovation.

Dry mixing fiberization technology improves the compaction density and energy density of solid-state batteries

1.Powder mixing and fiberization:Dry mixing fiberization technology combines active materials and conductive agents tightly through high-speed shear force to form a strong self-supporting electrode film.This technology can effectively improve the uniformity and dispersion of electrode materials,thereby improving the compaction density.For example,the compaction density of dry electrodes can be increased by 8%-32%compared with wet methods,which directly reflects the degree of close stacking of materials in the electrode.2.Binder fibrillation:In the dry process,the binder is fiberized by high shear force to form a polymer network with rich pores.This structure not only improves the mechanical strength of the electrode,but also enhances the bonding force between the active material and the conductive agent,thereby improving the cycle stability and energy density of the battery.3.Optimization of manufacturing cost and efficiency:Dry mixing fiberization technology significantly reduces production costs and improves manufacturing efficiency through integrated equipment and automated processes.For example,the manufacturing cost of this technology has been reduced by 18%,including the reduction of equipment,labor and plant costs.This cost advantage makes the dry process more competitive in large-scale production.4.Dispersion and bonding of solid electrolytes:In solid-state batteries,dry stirring fiberization technology can also be used for the dispersion and bonding of solid electrolytes.Through high-speed shear force,the solid electrolyte can be evenly dispersed in the polymer matrix to form a network structure with rich pores.This structure not only improves the conductivity of the electrolyte,but also enhances the overall performance of the battery.In summary,the dry stirring fiberization technology significantly improves the compaction density and energy density of solid-state batteries through core technologies such as powder stirring,fiberization,uniform powder spreading,multi-roller electrode transfer,multi-roller thickness closed loop,electric cutting and binder fibrillation.

Mechanism of improving compaction density

Fibrillated binder constructs a three-dimensional network skeleton:Traditional wet process defects:In the wet process,liquid solvents are used to dissolve binders(such as PVDF).After drying,the binder wraps the particles in a dot or flake shape,occupies space and is unevenly distributed,which hinders the close stacking of particles.Advantages of dry fiberization:High-speed shearing/extrusion fibrillates binders such as PTFE to form a micro-nanoscale,high aspect ratio fiber network.These fibers are like"rebars":Connecting particles:Effectively"bundling"active materials,solid electrolytes,and conductive agent particles together to provide strong mechanical support.Reserved space:The fiber network structure itself has elasticity and pores.During the subsequent rolling process:The fibers can be stretched/deformed to a certain extent,rather than rigidly blocked.Allow particles to rearrange and slide more effectively under pressure and fill in the gaps reserved in the fiber network.Reduce the volume share of binders:A strong fiber network only requires less binder(such as PTFE content can be reduced to 1-1.5%)to achieve or even exceed the bonding strength of the wet method,reducing the volume of inactive substances.Solvent-free elimination of"barrier layer":The evaporation of solvents in the wet process will leave a very thin binder"film"on the surface of the particles or form voids,hindering direct contact between particles.The dry process completely avoids solvents,enabling more direct and intimate physical contact between particles and between particles and the conductive agent/electrolyte.

Tags:

Battery Dry Mixer Fiberization Technology

Intensive Mixer

Lithium battery mixer

Back To The List