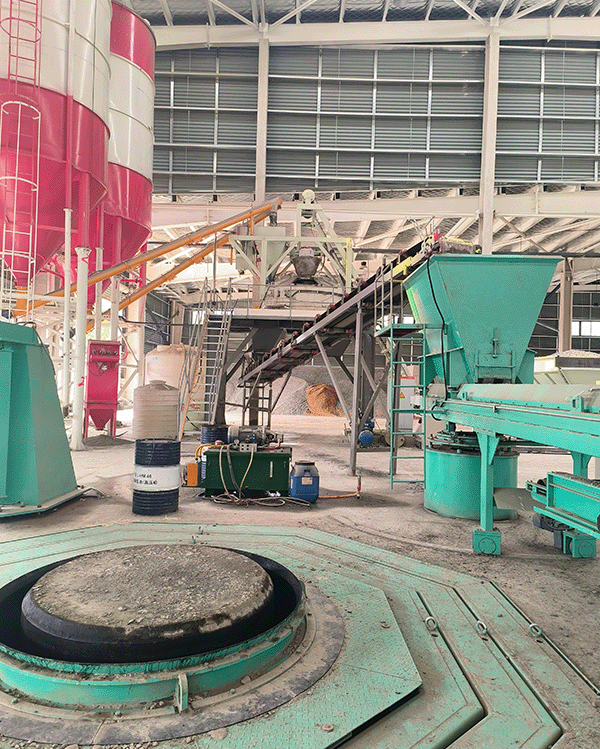

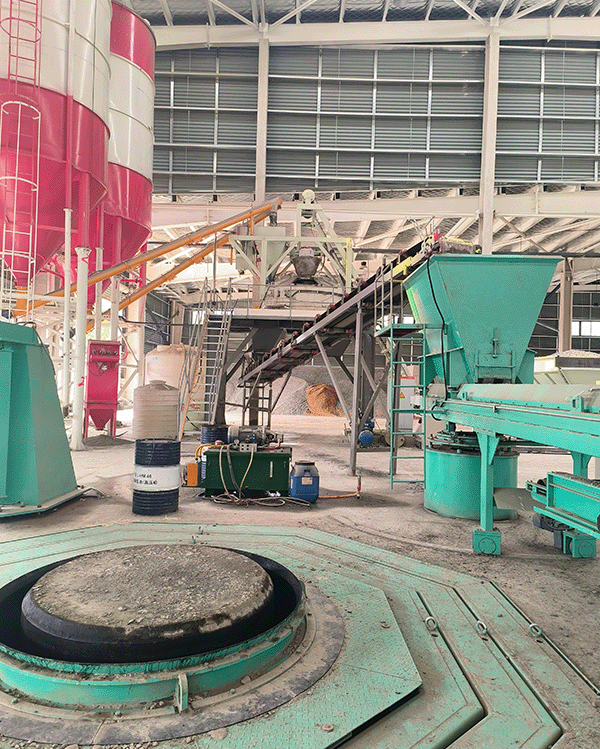

Modern Machinery Powers Up:2-Cubic-Meter Planetary Mixer&Automatic Pipe Machine Boost Concrete Pipe Quality&OutputSaudi Arabia–A significant leap in concrete pipe manufacturing efficiency and quality is being achieved,the integration of a state-of-the-art 2-cubic-meter Planetary Concrete Mixer and a fully Automatic Pipe Making Machine.This powerful combination is setting a new standard for producing high-grade concrete pipes used in critical infrastructure projects.

Precision Mixing for Superior Concrete

At the heart of this upgraded production line is the robust 2-cubic-meter Planetary Mixer.Unlike conventional mixers,its unique planetary motion–where multiple blades rotate on their own axes while orbiting the central axis of the mixing pan–ensures unparalleled homogeneity and consistency in the concrete mix.Key Advantages:This intensive mixing action guarantees thorough blending of aggregates,cement,and water,eliminating pockets of weakness or inconsistent curing.The result is a denser,more durable concrete mix essential for pipes that must withstand heavy loads,internal pressure,and harsh environmental conditions.The 2m³capacity provides optimal batch sizes for feeding the automated pipe machine efficiently,minimizing downtime between cycles.Automated Excellence in Pipe FormationThe mixed concrete is seamlessly transferred to the Automatic Pipe Making Machine.This sophisticated equipment automates the core processes of pipe formation:Precision Molding:Concrete is precisely fed and compacted into high-strength steel molds under controlled vibration and pressure.Consistent Curing:The machine often integrates initial curing stages under optimal conditions(steam or temperature control)to ensure uniform strength development from the outset.Automated Demolding&Handling:Finished pipes are automatically demolded and transported for final curing or storage,significantly reducing manual handling and potential damage.Key Advantages:Automation delivers exceptional dimensional accuracy,consistent wall thickness,and a smooth,high-quality finish on every pipe.It drastically reduces labor requirements and human error while significantly boosting production output and repeatability.

Driving High-Quality Production

The synergy between the 2m³Planetary Mixer and the Automatic Pipe Making Machine directly translates to tangible benefits:Enhanced Pipe Quality:Superior mix consistency leads to pipes with higher compressive strength,better density,improved abrasion resistance,and longer service life.Increased Production Capacity:Automated processes allow for faster cycle times and higher daily output of pipes in various diameters(typically from 300mm up to 2000mm or more,depending on the specific machine).Reduced Operational Costs:Efficiency gains,lower labor costs per pipe,and minimized material waste contribute to a healthier bottom line.Improved Safety&Working Conditions:Automation reduces strenuous manual tasks associated with mixing and handling heavy molds and pipes.Reliable Supply:Consistent,high-volume production ensures reliable fulfillment of contracts for municipal drainage,sewer systems,culverts,and other infrastructure projects."This investment in the planetary mixer and automatic pipe machine is transformative for our operation,"stated Production Manager of Saudi Arabia Company"We are now producing concrete pipes of consistently exceptional quality at a pace and efficiency level we couldn't achieve before.This directly benefits our customers who rely on durable,reliable pipe solutions for critical infrastructure.The precision from the planetary mixer is fundamental to the performance of the pipes coming off the automated line."About the Technology:Planetary Mixers:Known for intensive,fast,and homogeneous mixing,ideal for high-performance concrete and exacting specifications.Automatic Pipe Making Machines:Utilize processes like centrifugal spinning,vertical vibration,or roller compaction,combined with automation for feeding,compacting,curing initiation,and demolding.

Tags:

Concrete Pipe Making Machine

Planetary Concrete Mixer

Concrete Mixer

Back To The List